1.0

System Overview 系统概述

1.1 System Description

系统描述

系统描述

![]() PaR designed and developed the Vector2® Robot product

line for a cost effective high accuracy robot for smaller work envelopes in 5’

x 10’ x 1’ and 5’ x 12’ x 1’. The

Vector2® is provided with

3 axes of motion. The X and Y axes

are servo motor driven and controlled by our powerful CIMROC® PC based open architecture controller and the Z axis is electric

motor driven.

PaR designed and developed the Vector2® Robot product

line for a cost effective high accuracy robot for smaller work envelopes in 5’

x 10’ x 1’ and 5’ x 12’ x 1’. The

Vector2® is provided with

3 axes of motion. The X and Y axes

are servo motor driven and controlled by our powerful CIMROC® PC based open architecture controller and the Z axis is electric

motor driven.

PaR系统公司设计开发的Vector2® 机器人生产线作为低成本高精度的机器人,适于 5’ x 10’ x 1’和5’ x12’ x 1’的加工区域。Vector2® 提供3轴运动。X和Y 轴由伺服电机驱动,并由基于开放式结构的高效CIMROC® PC控制器控制,Z轴由电机驱动。

PaR provides this robotic process cutting system as a turnkey project.

PaR系统公司可提供这种机器人切割系统的交钥匙工程

Summary of Work Envelope

加工区域概述

The following table displays the work envelope of the major axes.

下表是主要轴的加工区域

1.2

Scope of Supply

供货范围

1.2.1

Summary of Equipment

设备摘要

|

Item 项目 |

Quantity 数量 |

Description 描述 |

|

1 |

1 |

VECTOR

2 Positioning System定位系统 |

|

2 |

1 |

CIMROC®5000NT CNC Controller控制器 |

|

3 |

1 |

I.R.

50 Hp Intensifier Pump增压泵 |

|

4 |

1 |

IR

High Pressure Delivery System高压水传送系统 |

1.2.2

Summary of Services Provided

提供服务摘要

System Documentation

系统资料

Spare Parts

零备件

System Installation Services

系统安装服务

System Training

系统培训

24小时服务热线

2.1

VECTOR2® Waterjet Cutting

System

VECTOR2® 水切割系统

2.1.1

Description

描述

The Vector2® requires three phase 380-volts with

50 Hz and 150 amp service.

The Vector2® requires three phase 380-volts with

50 Hz and 150 amp service.

Vector2® 所需的电源为3相380伏50赫兹150安

2.1.2

Major Features

主要特点

The Vector2® has many features not found in other waterjet cutting systems including the following:

Vector2® 有许多其他水切割机 所没有的特点,包括如下:

High capacity steel support structure and retractable cantilever arm allows for open access to the cutting area

高强度钢支撑结构和可缩回的悬臂结构,允许自由接近加工区域。

Heavy-duty, industrial grade machine designed to run multiple shifts

重型、工业等 级机械设计,可做联动加工。

Ingersoll Rand 50 HP intensifier pump

“Ingersoll Rand” 50匹马力增压泵。

14’ by 15’ footprint

14’x15’外形尺寸。

No system homing yields higher throughput from reduced start-up and recovery time completely eliminating the potential for collisions during homing operation

系统不用 回零,减少了启动和恢复的时间 ,提高了产量,完全消除了 在回零操作时潜在的碰撞。

Precision ball screws allow for excellent accuracy

精密滚珠丝杠,提供极高的定位精度。

Linear bearing rails for precision guidance

线性轴承导轨用于精密导向。

Low maintenance lubrication intervals on bearing blocks

对轴承滑块的保养润滑的时 间间隔长。

Stainless steel magnetic covers on X and Y axes prevent contamination for both the racks and linear ways, Z axis is a self-contained, sealed unit

在X和Y轴上带有无锈钢 磁性护罩以防止灰尘进入 滑轨和 线性导轨内,Z轴安装在一个壳体内 并具有密封装置。

All moving components (bearings, ball-screws, motors) have greater than a 20,000-hour life

所有可移动部件(轴承,滚珠丝杠,电机)都具有超过20,000小时的使用寿命。

Positive pressure on X, Y, and Z axes to eliminate contamination of linear ways and ball screws

在X,Y,Z轴上有正压吹气装置,以消除线性导轨和滚珠丝杠上的 灰尘。

2.1.3

Components

部件

The Vector2® System consists of the following major assemblies and subassemblies:

Vector2® 系统包含了下列主要总成和部件 :

Support structure consisting of a welded base structure

支撑结构由 一个焊接的基座组成

Cantilever arm with dual ball screw drive system

悬臂和双滚珠丝杠驱动系统

Mast assembly with dual ball screw drive system

主轴箱总成和双滚珠丝杠

CIMROC®5000NT controller

CIMROC®5000NT控制器

Ingersoll Rand 50 HP intensifier pump

英格索兰50匹马力增压泵

Support Structure

支撑结构

The support structure is a steel welded structure which supports the X, Y, and Z axes. The support structure also acts as a housing for the pump to decrease the footprint size of the system and to protect the pump from the water and abrasive.

支撑结构是一个 钢焊接结构 用于支撑X,Y,和Z轴。支撑结构 同时也是高压泵的 机座,以减少系统的外形尺寸,保护高压泵 不受到水和磨料的侵蚀。

Cantilever Arm

悬臂

The cantilever arm is completely retractable to remove the arm from the work envelope allowing full access to the cutting table. The X and Y axes of the cantilever arm are driven by servo motors. The Z axis is driven by an electric motor. Each of the axes are driven by dual ball screws.

悬臂可完全从加工区域收回 以允许全方位接近切削台。悬臂的 X和Y轴由伺服电机驱动,Z轴由电机驱动。每个轴的驱动都是由双滚珠丝杠来完成。

Ingersoll-Rand Pump

英格索兰高压泵

The Vector2® comes standard with 50 HP intensifier pump. The pump uses standard programmable dual pressure control. It has an exclusive long, slow stroke and minimal cooling water requirements.

Vector2® 配备50匹马力增压泵。增压泵泵使用标准可编程双压控制。泵具有独有的长距离慢冲程和最少量的冷却水需求的特点。

Please find the following information regarding typical component life for the Ingersoll-Rand Streamline SL-IV Plus Waterjet Intensifier. Please note that this information is based on maximum flow rate (1 gpm) at 55,000 psi. Lower flow rates and/or operating pressures would affect component life in a positive manner. Substandard water quality will have a detrimental effect on component life.

下面是关于英格索兰流线型SL-IV增强型水切割增强泵的典型部件使用寿命的信息。请注意,这些信息是建立在压力为55,000 psi时最大流量的基础上的。用正确的方式降低流速和/ 或操作压力可延长部件的使用寿命。质量等级差的水质将对部件的使用寿命产生不利影响。

|

Component 部件 |

Duty Cycle 使用周期 |

|

Diamond Orifice (for abrasive use) 金刚石喷嘴(供磨料使用) |

1,000 hours |

|

Focusing Tube (for abrasive use) 聚焦管(供磨料使用) |

80-100 hours |

|

Pneumatic Valves* 气阀 |

100,000 cycles |

|

High-Pressure Seals 高压密封垫 |

300-350 hours |

|

Hydraulic Cartridge Seal 液压套筒密封 |

500 hours |

|

High-Pressure Cylinder 高压缸 |

3,000 hours |

|

Check Valve* 单向阀 |

500 hours |

|

Ceramic Plunger 陶瓷活塞 |

4,000 hours |

|

Hydraulic Piston* 液压活塞 |

4,000 hours |

|

Seal Head Seals 密封头密封垫 |

600 hours |

|

Hydraulic Oil Filter 液压油过滤器 |

6 months |

|

LP Water Filter 水过滤器 |

6 months |

Milling and drilling spindle (

Optional )

铣削钻削主轴 ( 可选)

The spindle is a Perske 5HP 5000 to 18000 RPM programmable. The spindle is located on the mast with the waterjet head and can be manually positioned via pendant control in the Z direction. The system can be either router or water controlled by the operator.

该主轴由Perske制造,功率为5马力,可编程转速为5000到18000转/分钟。该主轴同水切割头并排安装机床Z轴上,可通过手持控制器手动操作在Z方向上定位。安装该主轴后,操作者可控制机床进行铣削或着进行水切割。

2.1.4

Special Features

特点

High Efficiency Drive

Assemblies

高效驱动总成

The design of the linear drive assemblies ensures maximum speed and power efficiency, while maintaining quiet operation and excellent repeatability and accuracy. All axes are driven by a high-torque servomotor system through controlled anti-backlash reducers. The gear reducers are sealed units requiring periodic lubricant change.

线性驱动总成的设计 可确保在保持安静操作前提下和极高的重复定位精度 与定位精度的条件下的高速度和高功效。所有轴的驱动由高扭矩伺服电机系统通过控制 具有反向间隙补偿的减速器来完成。齿轮减速器是整体密封装置需 要定期更换润滑剂。

Cabling

电缆

Wiring through the bridge, carriage, and mast axes uses flexible cable track systems. All discrete wires are marked with their numbers in accordance with the elementary diagram.

Electrical cabling to the system consists of multi-conductor cables for the motors, brakes, an feedback encoders. Power and signal cables are UL listed, type CL3 control cables and type TC power cables, with Hypalon jackets. Signal cables incorporate individually twisted, shielded pairs, with extra-flexible stranding for sensitive feedback circuits. Connectors on the system are heavy duty MS-type. Overall, shields and EMI style metal connectors used on system power and signal cables reduce electromagnetic interference (EMI), emissions, and susceptibility.

对通过桥,托板和主轴箱的电缆布线采用可弯曲的电缆拖链系统。所有分立的电线均标 上了一个和电 器原理图 相一致的线号 。连接到系统的多芯电缆包括电机,制动器和反馈编码器的电 缆。在 UL标准中 列出 了电源线和 信号线的型号,控制电缆是CL3型,电源电缆 是TC型,并且都包有Hypalon外套。信号电 缆由信号线绞合,包裹双层屏蔽, 并额外增加了一 软绳制成,可传输敏感的反馈电路信号。系统上的接线插头是 重型MS型。总之,用在系统的电源和信号电缆上的屏蔽和EMI形金属插头可减少电磁干扰,信号衰减及磁化。

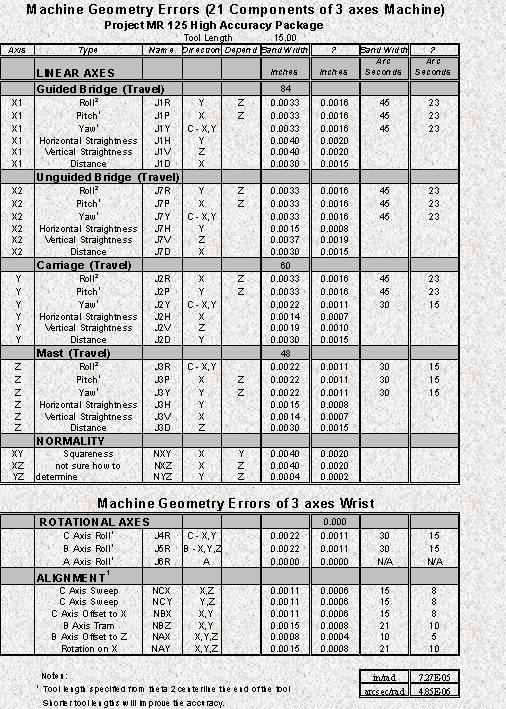

1.1.1

High Accuracy Package

The MR125 can be provided with a high accuracy

package for precise material removal applications. The accuracy is achieved by the addition of anti- backlash

gearing and using PaR’s Mechanical Error Compensation (MEC) software.

Split Gear

Rack and Pinion Drive System

In order to achieve precision positioning, a split

gear, rack and pinion drive system is used. This system effectively eliminates

backlash by using two pinions – one to drive the axis and one to pre-load the

axis. Eliminating the system

backlash provides accurate axis positioning during the transition period

between acceleration or steady-state and deceleration, when the load reverses

direction. The mechanical pre-load is achieved using a torsion spring to load

one fixed pinion against the other spring-loaded pinion. To ensure no backlash develops, the

pre-load torque is set higher than the deceleration torque. The preloaded system consists of the

gear rack, spilt pinions, and one reducer/motor drive system.

2.1.5

Reliability

可靠性

PaR robotic systems achieve high reliability through a number of design factors including the following:

由于许多设 计因素的作用 ,PaR公司的机器人系统可以达到很高的可靠性,这些因素包括:

4 generations of robots and controllers since 1980 (20 years) with over 1000 systems fielded in similar applications

从1980年(20年前)起开 发了4代机器人和控制器 ,超过1000个系统正在使用。

Identification of all weak components and redesign or replacement with larger, more rugged units

对所有易损部件进行鉴定 并且进行重新设计或者用 较大的更坚固的部件更换。

Implementation of controller part-count reduction program that has reduced controller component count by 66% since 1981 dramatically improving reliability

自1981年以来,实施了控制器零件减少计划 ,使控制器的零件数量减少了66%,显著的提高了可靠性。

2-hour MTTR on highest controller failure items including power supplies (40,000 MTBF), and motor drives (60,000 MTBF)

控制器故障的平均修复时间最 高为2小时,故障项目包括 电源(40,000小时的平均故障间隔)和电机驱动(60,000小时的平均故障间隔时间)。

Recommended system Preventative Maintenance schedule every 1 to 2 months

推荐的系统预防性保养表 提供每1到2个月的保养计划。

Complete enclosure of brushless motors with 90,000 MTBF from vendor (MTTR is 4 hours)

无刷电机完全封闭,且卖方提供 90,000小时的平均故障间隔(平均修复时间为4小时)

Utilization of special test fixtures in-house to flex-life test all new cable assemblies

在我们内部利用专门的测试设备对所有新电缆组件进行绕度寿命实验。

2.1.6

Safety Features

安全特性

AlSpindle Runout per NAS 985 - 4.3.10.1

Radial

- 0.0003” T.I.R.

Axial - 0.0002” T.I.R.

Cutting

Tests

Overshoot and Undercut Test per NAS 979

4.3.3.4

Accuracy and Repeatability Cutting Test per

NAS 979 4.3.3.11

Position

accuracy is the degree of precision a robot exhibits in an initial attempt to

acquire any target point, as in manufacturing applications. The actual point obtained must be

within a specified tolerance of the target point, regardless of whether the

target point is a taught or an intended point. This specified tolerance can be thought of as the radius of

an imaginary sphere surrounding the target point bulls-eye in three dimensional

space. The sphere represents the

total position accuracy error bandwidth of the robot.

Robot Repeatability (Definition)

Repeatability

is the degree of precision a robot exhibits in returning to a previously

acquired point. The repeated point

must be within a specified tolerance of the previously obtained point. This specified tolerance can be thought

of as the radius of a second imaginary sphere surrounding the previously

obtained point bulls-eye in three dimensional space. The repeatability sphere would be smaller and contained

somewhere within the position accuracy sphere. The second sphere represents the

total repeatability error bandwidth of the robot.

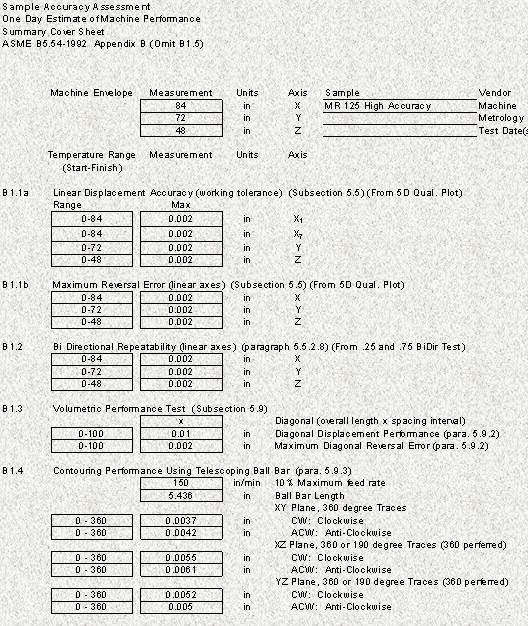

Sample

Accuracy Summary Sheet

The

following table provides a summary of the machine accuracy assessment and

includes displacement accuracy, reversal errors, bi-directional repeatability,

volumetric accuracy, and dynamic contouring accuracy. Please note that no errors or alignment errors of the work

table are included since these errors are not applicable when using the

Renishaw SP2-1 probe and PaR’s probe software to do 6-dimensional transformations.

Sample

Accuracy Components Summary

The

following table provides a summary of all the major error components associated

with each axis of motion. It is

important for the end user to be aware of the different components, which make

up the overall accuracy, to be able to make a comparison of vendor’s quoted

accuracy specifications.

All safety devices for human and

machine protection are designed into the locomotion and control system to the

latest OSHA and RIA government and industry standards.

在运动和控制系统 中设计了所有人和机床的安全保护装置 ,符合OSHA和RIV政府和工业标准。

Programmable boundaries (soft limits) define operational range

可编程的加工区域边界(软极限)限定了机器人的操作范围。

A hard-wired limit switch (hard limit) halts the system in the event of an axis over-travel due to operator or control system fault

因操作人员误操作 或控制系统故障而使 某个轴运动超过行程 时,硬限位开关(硬极限)将使机器停止。

Shock absorber bumpers (hard stops) absorb impact energy should a catastrophic control failure cause the system to exceed its soft limits and hard limits

一旦出现毁坏性的故障 ,使机器人的软极限和硬极限失去作用时,吸振档块(硬限位)将吸收冲击能量。

Low control voltages throughout the electrical system helps safeguard personnel from potential shock hazards caused by equipment damage or human misjudgment

整个机器人的电器系统采用低电压控制,帮助避免可能由于设备 损坏和人为判断失误而引起的潜在事故。

Standard emergency stop (E-STOP) switches on the operator panel and teach pendant provide an emergency shutdown mechanism for halting the system in the event of unanticipated movement. A standard STOP switch on the operator panel provides a routine shutdown mechanism for halting the system

在操作面板和悬挂操作盘上的标准急停开关 可在机器人出现无法预知的移动时,使机械部分急停。在 操作面板上的停止开关可使 机械部分停止运动从而使系统暂停。

Expandable standard industrial I/O modules provide ample signal and control paths for additional sensing, safety, and control circuits

可扩展的标准I/O模块,提供了充足的信号和 控制通道,以便增加传感器,安全开关和控制回路。

Motion control system monitors the axes and safely shuts down upon detection of loss of feedback, excessive following error, or excessive motor current. A watchdog timer circuit shuts down the system upon failure of the motion control computer

运动控制系统 可监测轴的状态,并在丢 失反馈信号 ,跟踪误差超差或电机过流时 使系统安全停止。当运动控制 计算机出现故障时 ,监控 定时电路可使系统停止。

Hand held teach pendant for operating the system manually and teaching point data

手持控制器用于手动操作系统和 示教点位数据。

2.2 CIMROC®5000NT Controller

CIMROC®5000NT

控制器

CIMROC®5000NT Controlle

r

The CIMROC®5000NT Controller’s advanced functions allow users to perform complex CNC tasks. The CIMROC® controller provides a complete range of motion control, including multiple coordinate systems, straight-line tool tip motion, time-optimized interpolation, and circular interpolation in absolute, relative, and transformed frames.

CIMROC®5000NT提供了先进的功能允许操作者 执行复杂的数控程序。控制器可提供全范围的运动控制, 包括多坐标系统,刀尖直线运动,时间优化插补, 绝对坐标及相对坐标圆弧插补,位置变换。

The CIMROC® is operated utilizing an included application that facilitates editing and execution of Industry Standard RS-274D machine code programs. These programs consist of M and G codes defining the mode and path for complex contouring. The environment is extended to include support for advanced features specific to the application and process peripherals. These often consist of such devices as an automatic end-effector changer, Renishaw probe, or intelligent drill.

利用易于编辑和执行,并符合RS-274D工业标准的机床代码程序可操作CIMROC® 控制器。这些程序 由 定义 复杂轮廓的加工方式和路径的 M和G代码组成。扩展的操作环境包含了对先进功能的支持功能 ,特别是外围设备的应用和处理。这些外围设备通常由诸如自动交换器,Renishaw测头或灵活的钻削装置 组成 。

The CIMROC® features advanced data processing capabilities, analog and digital I/O, and network and serial communications. The open control architecture is based on modular, multi-tiered, distributed processor design. This design enables separate, simultaneous control of supervisory, trajectory, and servo functions. It also provides maximum flexibility in hardware to integrate advanced, real-time motion control options including intelligent interfaces for vision, force-tactile, and surface following.

CIMROC® 控制器具有先进的数据处理能力,配备有模拟和数字 I/O接口,网络和串行通讯接口。控制器采用基于 模块化的开放式结构 ,分布式处理器 设计。这种设计允许将控制器分成 联动控制处理器 ,轨迹控制处理器 和伺服功能 部分。控制器在硬件设计上极具灵活性,可安装先进的积分选件,实时运动控制选件,包括显示器接口,压力传感器接口和表面跟踪接口。

The controller supervisor is a high speed, Pentium single board computer residing on a passive PCI/ISA back plane. It supports standard hardware options such as various graphics display adapters, additional hard disk storage, extended memory, various LAN products, multiple intelligent and non-intelligent serial ports, and other third-party hardware. Sophisticated software packages are available which significantly expand system capabilities including CAD/CAM, local area networks and other host communications, data base management, office applications, and graphics.

控制器的主处理器 是一个高速 Pentium芯片,安装在一块无源的PCI/ISA底版上。可支持标准硬件选件,例如 各种图形显示适配器 ,扩展硬盘,扩展内存 ,各种网络产品,多指令和无指令 串行端口,以及其他的第三方硬件。高级软件包可有效的扩展系统的加工能力 ,软件包括 CAD/CAM软件,局域网和 其他的主机通讯软件,数据库管理软件, 办公软件,和绘图 软件。

2.2.1

Features

特点

Multiprocessor-based, distributed architecture

多处理器设计,分布式结构

Standard Microsoft Windows® NT/Windows® 2000 operating system

标准Microsoft Windows® NT/Windows® 2000操作系统

Standard CNC Emulation Application (CIMSys) supporting RS-274D part programming

标准数控仿真应用软件(CIMSys),支持 RS-274端口程序

Standard General Purpose Diagnostic and Maintenance Application Program (PaRUtil) enables testing of the CNC machine and motion control system

标准通用故障诊断和维修应用程序(PaRUtil),允许检测数控机床和 运动控制系统

Straight line, time optimal, and circular motion types using polynomial contouring algorithms

利用多重轮廓算法可进行直线,时间优化和圆弧类型的运动。

Absolute and relative point coordinate data

绝对和相对点坐标数据编程

Point transformation functions

点位数 据转换功能

Host communications/LAN support

支持主机通讯 / 局域网

Complete digital and analog industrial I/O control

完整的数字和模拟 工业 I/O控制

Off-line programming

离线编程

Noise free fiber optic communications between computers and CNC machine motor drives

计算机和数控 机床驱动器之间 采用无干扰的光纤通讯

2.2.2

Standard Hardware Devices

标准硬件装置

Pentium Supervisory CPU

Pentium监控CPU

Pentium Trajectory CPU

Pentium轨迹控制CPU

Digital Signal Processor (DSP) Motion Control Processor

数字信号处理器(DSP),运动控制处理器

VGA flat panel video display, 10.4 inch TFT, color

VGA纯平显示器,10.4英寸彩色TFT显示屏

Floppy disk storage, 3 1/2 inch, 1.44Mb

3.5 英寸,1.44Mb软驱

High capacity hard drive

大容量硬盘

Dynamic RAM memory (Minimum of 32Mb provided)

动态 RAM内存(最小容量32Mb)

I/O motherboard (8 digital inputs and 8 digital outputs, capable of supporting up to 32 I/O). I/O bus expandable to 512 digital and analog I/O

I/O板(8位输入,8位输出,支持32I/O)。I/O总线可扩展到 512位数字和模拟 I/O

QWERTY-style keyboard with numeric keypad, mouse and function keys

带键区,鼠标和功能键 的标准键盘

NEMA-12 grade enclosure with ventilation fans with filters

符合NEMA-12标准的电器柜,装有 换气扇和过滤网

Teach pendant with a 50-foot cord

带50英尺长电缆的 手持控制器

Dual channel emergency stop and safety stop circuitry

双通道急停开关和 安全关断电路

2.2.3

Optional Hardware Devices

可选硬件装置

Ethernet and RS-232/485 serial communication ports

以太网和RS-232/485串行通讯端口

Modem

调制解调器

Thermostatically controlled air conditioning (operating range of 40° to 125° Fahrenheit)

控温空调(可操作范围从40到50华氏度)

2.2.4

Teach Pendant

手持控制器

The teach pendant is a hand held serial terminal used for operating

the system manually and teaching point data. It is connected through a cable to the control console. The teach pendant is equipped with an

emergency stop push-button and three position enabling switches satisfying

ANSI/RIA 15.06-1999. The pendant

has an 8 line by 20-character alphanumeric display, a feed rate control switch,

and a sealed industrial keypad.

The keypad consists of system keys (used to control and modify robot-operating

parameters), function keys, drive keys for operating each axis of the robot,

and application keys.

The teach pendant is a hand held serial terminal used for operating

the system manually and teaching point data. It is connected through a cable to the control console. The teach pendant is equipped with an

emergency stop push-button and three position enabling switches satisfying

ANSI/RIA 15.06-1999. The pendant

has an 8 line by 20-character alphanumeric display, a feed rate control switch,

and a sealed industrial keypad.

The keypad consists of system keys (used to control and modify robot-operating

parameters), function keys, drive keys for operating each axis of the robot,

and application keys.

手持控制器 是一种手持系列终端设备,用于手动操作系统和 示教点位数据 。通过一根电缆 将手持控制器 连接到控制台。手持控制器上装有一个 急停开关按扭和三位使能开关,符合ANSI /RIA15.06-1999标准。手持控制器上 配备有一个8行每行26字符的显示器, 一个倍率控制按扭和一个密封的工业键盘 。键盘由系统键(用于控制和修改机器人操作参数),功能键 ,操作机器人每一个轴的驱动键和应用键组成。

2.2.5

Operational Modes

操作方式

Because of the unstructured nature of many tasks, a variety of control and operational modes are available ranging from manual tele-operation to full robotic control. The CIMROC® can supplement the motion resulting from these operational modes using sensor information to compensate for inaccuracies.

因为要完成 许多不同的 任务,可以使 用 从远程控制方式到全功能机器人控制方式 的各种控制和操作 方式。CIMROC® 可对运动误差进行 补偿,因为这些操作方式均使用传感器反馈 误差补偿信息。

CAD/CAM Off-Line Programming

离线编程

The CIMROC® can process tool paths generated with your existing CAD/CAM system off-line, and can easily be downloaded over your network. Uninterrupted production is maintained by programming parts off-line and queuing jobs to the controller. Additionally, CAD/CAM programming is simplified as the CIMROC® controller automatically adjusts the programmed velocities for tight radii and abrupt contour changes to provide a superior surface finish.

CIMROC® 控制器能 利用已存在的 CAD/CAM离线系 统 产生刀 具轨迹,并且能 容易的在 网络上下载 。控制器 可保存 连续下载 的程序并且进行重新排列。 而且控制器 可简化CAD/CAM程序,调整 程序中的加工速度, 以便 在加工 圆弧和轮廓突变的工件时 产生极高的表面精度。

2.2.6

Configuration

配置

The standard CIMROC®5000NT incorporates the control computers, system interface circuitry, motor drives, and system I/O in a single enclosure. Modular enclosure design allows the use of matching expansion enclosures to accommodate systems requiring additional space for extended I/O requirements and/or auxiliary equipment. Controller enclosures conform to NEMA-12 standards.

标准的CIMROC®5000NT控制器 由包括在同一个电器箱中的 控制计算机 ,系统接口电路,电机驱动器和系统I/O接口组成。模块化的电器箱设计 结构允许使用相匹配的电器箱 扩展空间,以便 满足扩展I/O和 / 或 外围设备所需的空间。控制箱符合NEMA-12标准。

The controller has an electrical disconnect switch with front door interlock, per NFPA 79. Doors of expansion cabinets, when provided, are also interlocked with the disconnect switch. The flat panel video display, keyboard, and emergency stop (E-STOP) pushbutton are located on the front of the controller.

控制器内 装有一个和前门 互锁的电子断路开关,如果需要 每一个符合 NEPA 79标准的电器柜扩展门也可和断路开关互锁 。纯平显示器,键盘和急停开关按扭安装在控制器的前部。

Multiple, guarded, ventilation fans handle cooling of the controller. Air filters are utilized on all air inlets and exhaust openings. Optional air conditioning utilizes CFC free, closed loop systems.

带多重保护 格栅的换气扇 用于冷却控制器 。所有空气进出口都设有空气过滤器 。如果需要 可安装空调器,空调器采用CFC介质,闭环控制。

2.2.7

Motion Control Subsystem Features

运动控制子系统的特点

The motion control subsystem interprets position commands and performs mathematical computations for simultaneous coordination of multiple system axes with controlled

acceleration and velocity. The trajectory processor provides advanced path generation abilities, real-time tool transformations, and complex system kinematics. The digital signal processor executes closed-loop digital servo algorithms. “Real world” axis performance is monitored to minimize dynamic positioning errors and to detect and shut down the system in event of fault conditions. High performance pulse width brushless servo drives reduce thermal dissipation in the CIMROC® controller, reducing controller heat generation and saving power.

运动控制子系统用于解释位置命令,对系统各个坐标轴进行插补计算 和加减速控制。轨迹处理器可提供轨迹前看 功能,实时刀具转换功能和系统复杂运动的 控制功能。数字信号处理器 执行闭环全数字伺服算法 ,监控三维 空间内各轴的实际运动以达到最小的动态误差 ,当检测到故障时 又可关闭系统。高性能脉宽无刷交流伺服驱动减小了控制器的发热,节省了电能。

The motion control subsystem also contains a block look-ahead feature. The subsystem computes point density and angular deviation of upcoming points to bound the velocity in order to preserve the geometry defined by the points while striving to maintain the programmed velocity without exceeding the desired acceleration limits. This look-ahead feature results in smoother high-speed contouring and minimized vibration while maximizing processing velocity.

运动控制子系统也具有 程序块前看功能。 当力求保持加工速度而又不能超过 加速度极限时,为了保证 由点位定义的几何轮廓的精度,运动控制子系统可计算即将加工的点的密度和角度偏转值限定其加工速度。这个前看功能可使高速加工的轮廓平滑,当进行高速 切削时可使振动达到最小化。

2.2.8

Encoder

编码器

Position feedback is obtained using an absolute encoder mounted on the back of each servomotor. The encoder provides commutation, speed, and position information. The absolute encoders eliminate the need for homing on power-up, and have 26 bits of basic resolution, before interpolation, with 16,384 counts per motor revolution and up to 4,096 motor revolutions. They use an Industry Standard interface to provide reliable data transmission over long cable distances. Their SIN/COS type output allows interpolation to obtain very high position resolution (over 16 million counts per motor revolution) for exceptionally smooth motor operation.

位置反馈由安装在 每个伺服 电机后的绝对编码器提供 。 编码器可提供换向、速度和位置信息。绝对编码器 完全消除了启动后回零的需要。编码器具有 26位基本分辨率,电机每转有16,384个读数,可反馈的电机最高转数为4,096转。编码器采用标准 工业接口,数据可进行远距离可靠传输 。采用正余弦型输出,允许 输出高分辨率的位置信息(电机每转可超过16,000,000个读数),用于超平滑的电机。

2.2.9

CIMSysÔ

CIMSysÔ系统软件

![]()

![]()

![]() CIMSysÔ provides CNC control at the CIMROC®

console. It allows users to load,

edit, probe, transform, and execute programs using RS-274D machine tool codes

in a Windows® environment.

Additional capabilities include file management, communication, MDI

(manual data input), selected block execution, tool management,and process

level execution. CIMSysÔ extends RS-274D part programming by using custom miscellaneous or

"M" codes for controlling process equipment.

CIMSysÔ provides CNC control at the CIMROC®

console. It allows users to load,

edit, probe, transform, and execute programs using RS-274D machine tool codes

in a Windows® environment.

Additional capabilities include file management, communication, MDI

(manual data input), selected block execution, tool management,and process

level execution. CIMSysÔ extends RS-274D part programming by using custom miscellaneous or

"M" codes for controlling process equipment.

CIMROC®控制器的CIMSysÔ 软件提供 系统的数控控制 。允许 用户在 Windows® 环境下,使用 RS-274D机床 代码 下载,编辑,检测,转换 和执行程 序。该软件附加的功能包括 文件管理,通信,MDI(手动数据输入),选 择块 执行,刀具管理 和按等级执行程序的功能 。CIMSysÔ软件扩展了RS-274D端口程 序,便于用 户 使用各种辅助功能或 “M” 代码控制 设备。

CIMSysÔ also supports the ability to use both Metric and English units with the MRÔ125. A user selector switch allows the user to easily move between these two measuring systems.

通过安装MRÔ125软件,CIMSysÔ 也支持 英制和公制 两种测量系统 。用户通过 用户选择开关 可容易的在这两种测量系统之间切换 。

2.2.10

PaRUtil

PaRUtil软件

PaRUtil is an application program that enables technical support personnel to test the CNC machine and motion control system on the CIMROC®5000NT. PaRUtil uses an assortment of window driven menus to perform diagnostics on various elements of the system.

PaRUtil软件是一种应用程序 ,允许技术支持人员 在CIMROC®5000NT.控制器上检测数控 机床和 运动控 制系统 。该软件利用窗口分类 驱动菜单 对系统的各个部分进行诊断。

PaRUtil also assists in the setup of position feedback devices and can display current servo status information. Tests for the following hardware troubleshooting are included:

PaRUtil也参与位置反馈 装置的设置,并能显示 当前伺服的 状态信息。该软件检测下列硬件故障 ,包括:

Motion Control Interface

运动控制接口

Digital and Serial I/O

数字串行I/O口

Pendant

手持控制器

Digital Signal Processor Card

数字信号处理卡

Communication Card and Fiber Optic Link

通讯卡和光缆

Motor Drive

电机驱动器

Feedback Devices (encoders, resolvers, linear scales)

反馈装置(编码器,旋转变压器,光栅尺)

Brakes

制动器

Limit Switches and E-Stop Status

限位开关和急停开关状态

3.0

Acceptance Test Package 验收测试程序

PaR, along with the customer, will develop a mutually agreed upon product acceptance test package (ATP). This test package is to demonstrate specification compliance. Customer will approve the ATP before commencing testing. Following system erection, this test procedure will be performed at the installation site facilities. Successful completion of the test cuts and any special customer required tests will constitute final acceptance of the system.

PaR和用户一起制定双方都同意的验收测试程序。验收测试程序可验证技术规格是否符合。在测试之前,用户要认可验收测试程序。随着系统的安装,在安装现场开始执行测试程序。在成功的 完成了试切和用户特别要求的测试项目后,要 考虑最终验收该系统。

4.0

Installation Plan 安装计划

Customer will notify PaR when the system arrives on site and will provide the following:

当系统到达工作现场 ,用户要通知PaR公司,并提供下列设备:

One fforklift of 10,000 pound

minimum capacity

一台最小起重量为10,000磅的叉车

Miscellaneous equipment such as wrenches

辅助设备诸如扳手等

PaR will provide one field service technician to direct the assembly of the system. Installation supervision covers the placement of the basic robot and controller. PaR will provide one specialist to perform mechanical error compensation and accuracy testing.

PaR将派一名服务技师 指导安装过程。安装检查包括基本的机器人和控制器 护罩的安装。PaR,将派一名专家进行精度测试 ,对机械误差进行补 偿。

A complete system document package will be assembled into 3-ring notebooks. This package will include the following.

完整的系统资料 包被包装在 一个3环的资料薄中。这个资料包包括:

Mechanical Drawing Package includes copies of all major assemblies listed on the top level System Installation Drawing (SID)

机械图纸包,包括 所有主要零件的汇编表和 安装图

Electrical Drawing Package includes copies of all electrical schematics and interconnect drawings

电器图纸包,包括 所有电器图表的复本和 接线图

CIMROC®5000NT Product Manual provides a basic description and operating procedures of the controller

CIMROC®5000NT产品手册,提供了控制器的基本描述 和操作方法

CIMROC®5000NT Service Manual provides trouble shooting guides along with proper serving methods

CIMROC®5000NT维修手册,提供故障检修指导 和适合的维修方法

Vector2® Service Manual includes trouble shooting, servicing, lubrication schedules, and preventative maintenance schedules

Vector2® 维修手册,包括故障检修,维护保养 ,润滑图表和 预防性保养图表

Ingersoll-Rand operation and service manual

英格索兰高压泵操作和维修手册

Spare Parts List is a list all PaR recommended parts

备件清单,包括了PaR公司推荐的所有零件

CIMSysÔ Product Manual

CIMSysÔ软件产品手册

PaRUtil Product Manual

PaRUtil软件产品手册

6.0

Training Plan 培训计划

PaR provides the following training courses. Following the factory tests, training at PaR for customer personnel will begin.

PaR公司提供下列主要培训课程。在工厂测试之后,在 PaR公司将对用户人员进行培训。

6.1

Operator Training

操作培训

This course provides production personnel with the knowledge to operate the system using the product specific operation software for both local and network control. Upon course completion, students will have been instructed on the following:

本课程教授生产人员利用专门的操作软件 控制局域网和网络的系统操作知识。完成了本课程之后,学员可接受到下列指导 :

System components

系统的组成结构

Basic system operation including power up, program execution, and manual pendant control

系统的基本操作,包括电源开启,执行程序,和手动操作盘的控制

Basic CIMSysÔ and PaRUtil operation including logons, help screens, error screens, menu selections, editing, file processing, and error recovery

基本的CIMSysÔ和PaRUtil软件的操作知识,包括用户登记,帮助屏幕

错误提示屏幕,菜单选择,编辑,文件处理和故障 恢复

System peripheral operation and calibration

系统外围设备的操作和检查

Ingersoll-Rand basic intesifier pump system operation

英格索兰增压泵基本的操作知识

6.2

Maintenance Training

维修培训

The purpose of this course is to instruct maintenance and/or engineering personnel on theory of operation, basic operation, maintenance and effective troubleshoot of robot, controller, and custom peripheral equipment. This class is 32 hours in duration (4 sessions of 8 hours each).

本课程的目的是指导维修工程师和 / 或人员了解 操作的基本原理,学会基本的操作和维护知识,有效的检查机器人,控制器和 用户外围设备的故障。该课程共32学时(4天,每天8小时)

Upon course completion, participants will have been instructed on the following:

完成了本课程,学员将具备下列知识:

The identity and function of all hardware components of the CIMROC® controller

可检查CIMROC® 控制器所有的硬件功能

The identity and function of main components on the system

可检查系统主要部件的功能

The locations and means whereby all hardware components connect

了解所有硬件的连接位置和方式

How to interpret CNC machine schematic diagrams

学会如何看数控机床的原理图纸

Lubrication requirements including location, frequency, and type of lubricants

了解系统所需的润滑位置,频率和润滑类型

The identity and function of all hardware components on PaR custom peripheral equipment

可检查PaR公司提供给用户的外围设备的硬件功能

Basic Ingersoll-Rand intensifier pump maintenance

学会Ingersoll-Rand增压泵基本的保养知识

6.3

Software Training

软件培训

This course covers the operation of standard software modules such as CIMSysÔ and PARUtil. Surfcam training is optional with Surfcam purchase. PaR will train up to four operators. PaR’s facility will host the training course after the system acceptance tests.

本课程含盖了 诸如CIMSysÔ 和PARUtil 软件等标准软件模块的操作知识。软件培训是一个选项,可通过购买 选择该培训。PAR公司一次可培训4名操作者。在系统验收之后,培训在PAR的工厂进行。

6.4

24-Hour Service Hotline

24小时服务热线

PaR Systems maintains a 24-hour per day service hotline for the support of equipment supplied by PaR Systems. Our service technicians are trained in the assembly, installation, repair, upgrade, and modification of all equipment we manufacture. Mechanical and software engineers are also available for service calls when necessary. In addition, engineers and service technicians are available to answer telephone questions.

PAR系统公司设有24小时热线以对PAR系统公司提供的设备进行支持。我们的服务工程师均接受过我们所有设备的 装配,安装,维修,升级和调试的培训。当需要时,机械工程师和软件工程师也可提供服务。而且,工程师和服务技师通过电话直接回答您的问题。

The following codes and standards are used in the production of PaR robots and controllers:

PaR公司采用以下代码和标准控制机器人和 控制器的生产

Electrical

Standards---Robot Controller

电器标准---机器人控制器

ANSI/NFPA 70, National Electric Code®

ANSI/NFPA 70,《美国国家电器规程》

ANSI/NFPA 79, Electrical Standard for Industrial Machinery

ANSI/NFPA 79,《美国工业机器电器标准》

Safety

安全规程

ANSI/RIA R15.06, Industrial Robots and Robot Systems – Safety Requirements

ANSI/RIA R15.06,《工业机器人和机器人系统安全要求》

Materials

材料标准

ASTM, SAE

Welding

焊接标准

ASME Section IX Welding or

ANSI / AWS D1.1 Structural Welding Code

ASME第IX部分,焊接,或ANSI / AWS D1.1《结构焊接规程》

Construction

结构标准

ANSI/ASMI B15.1 Safety Standard for Mechanical Power Transmission Apparatus

ANSI/ASMI B15.1《机械传输安全标准》

ANSI/EIA-267-C Axis and Motion Nomenclature for Numerically Controlled Machines

ANSI/EIA-267-C 《数控设备轴和专用术语》

National Aerospace Standard NAS 938 Machine Axis and Nomenclature

《国家航空标准NAS938机械轴和专用术语》

ASIC Manual of Steel Construction

ASIC《钢结构手册》

Machine

Accuracy Standards (if applicable)

机械精度标准(在可应用的情况下)

ANSI/ASME B5.54 Methods for Performance Evaluation of Computer Numerically Controlled Machining Centers

用于电评数控加工中心的ANSI/ASME B5.54方法

QA Standards

---PaR’s QAMP-2 meets the following standards

QA标准--- PaR公司的QAMP-2满足下列标准

ISO 9001/EN29001/ANSI/ASQC Q9001-94, Certificate Number 50673, The Quality Management System is applicable to “The Designer and Manufacture of Industrial Robots, Manipulators, and Nuclear Handling Equipment”

ISO 9001/EN29001/ANSI/ASQC Q9001-94,认证号50673。质量管理系统适用于

“工业机器人,机械手,及核处理设备的设计和制造”

7.1

WARRANTY

保修

PaR warrants for one (1) year after commencement of the warranty period that all parts manufactured by PaR are free from defects in material and workmanship. The warranty

period shall begin upon the first of the following events to occur (i) the completion of installation; (ii) Buyer acceptance; or (iii) forty-five (45) days after delivery. The warranty will be fulfilled by repair or at the option of PaR, replacement of the defective part and will include the cost of parts and labor. For components, which are purchased by PaR, the original manufacturer’s warranty will be passed onto the Buyer. This warranty is subject to, and the Buyer agrees to the following:

PaR公司对其生产的零件因材料 和 工艺缺陷提供一 年的保修。在下列事件中 ,以先发生的事件的发生日起算保修 期:( i ) 安装完毕 。( ii )验收完毕,或( iii ) 发货45天之后。保修主要进行故障维修,更换损坏的零件,包括 零件花费和人员开销 。对一些 由PaR公司购买的零件,原 制造厂商的保修由 买方享受。为了保修承诺的实现,卖方应遵循以下原则:

Give PaR written notice of any claimed defect immediately upon discovery.

在发现故障后立即通知PaR公司

Provide easy access for PaR to inspect the claimed defective part in the configuration that the defect was discovered; and repair or replace the part.

用户应为PaR公司的技术人员提供赴现场 进行故障设备检查的条件,以便于 PaR公司及时发现故障所在,及时修复或更换损坏 零件。

This warranty applies only to the original Buyer.

保修仅适用于原买方

Parts shall not be returned without PaR approval.

没有PaR公司的同意零件不能返还

All parts replaced shall be the property of PaR.

所有零件的更换由PaR公司负责

No warranty is made with respect to the following:

下列不属于保修范围

Parts normally designated as consumables or those subject to normal wear and tear.

一些可消耗的或那些易正常磨损和断裂 的特别指定的零件

Failures or damage due to accident, abuse, improper operation or abnormal environmental conditions.

由意外事件,非正常使用,不正常的操作方式或 异常的环境 状况造成的故障或损坏。

Systems not installed by PaR or systems installed without PaR supervision, unless the Buyer has PaR’s prior written consent.

系统不是由PaR公司安装或系统安装没有受到PaR公司的监督,除非买方在这之前有PaR公司的书面同意。